Hazardous waste

Application Background

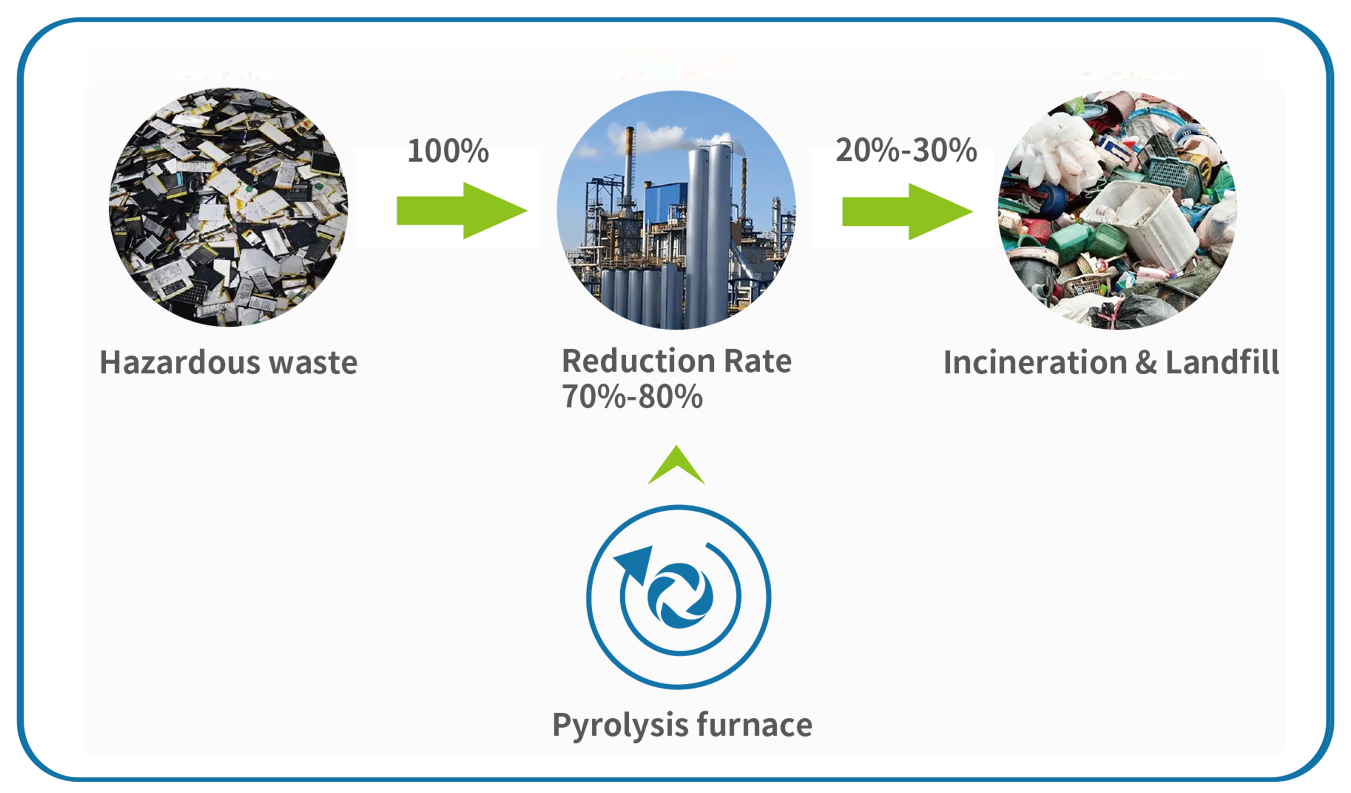

Industrial (chemical, pharmaceutical) production processes produce a large amount of hazardous waste, such as fine steam residue, oil sludge, paint residue, etc.; on-site capacity reduction is an excellent way to reduce production costs. Because of the single stream of the wastes, pyrolysis process is a perfect choice to treat this kind of waste.

Process Characteristics

Organic hazardous wastes are thermally unstable, under anoxic conditions, through heating to crack down the hazardous waste. After condensation, syngas, liquids, and solids are formed. The composition, calorific value, shape, and pyrolysis state of different batches of hazardous waste fluctuate significantly due to dangerous waste's complex physical and chemical property characteristics. Simultaneously, the composition of pyrolysis gas and the properties of waste residue will also change. Therefore, it is necessary to design an integrated pyrolysis reactor according to the characteristics of different materials to dispose of hazardous waste.

Typical Schematic

-

Next:Other waste