Industrial waste

Application background

Industrial production produces a large amount of waste, the traditional way is to transport out for incineration or to construct a centralized hazardous waste treatment plant. For the general industrial waste, sending to the incinerator treatment, costs not only much money in transportation but also in handling which increased the burden of waste production enterprises. The promotion of clean production processes in factories and the encourages of reduction at the source, bring in JADE heat treatment process in time to meet the requirements.

Process introduction

Industrial organic wastes are grinded prior to feeding into the pyrolysis carbonization system through the conveying system. During the pyrolysis carbonization process, the organic components with high calorific value are decomposed into mainly syngas and other solid and liquid products. After purification, a part of syngas is combusted in furnace producing high-temperature flue gas to provide heat source for the pyrolysis carbonization furnace. The remainder can be used to generate steam in gas-fired boiler systems or directly for power generation by gas engine.

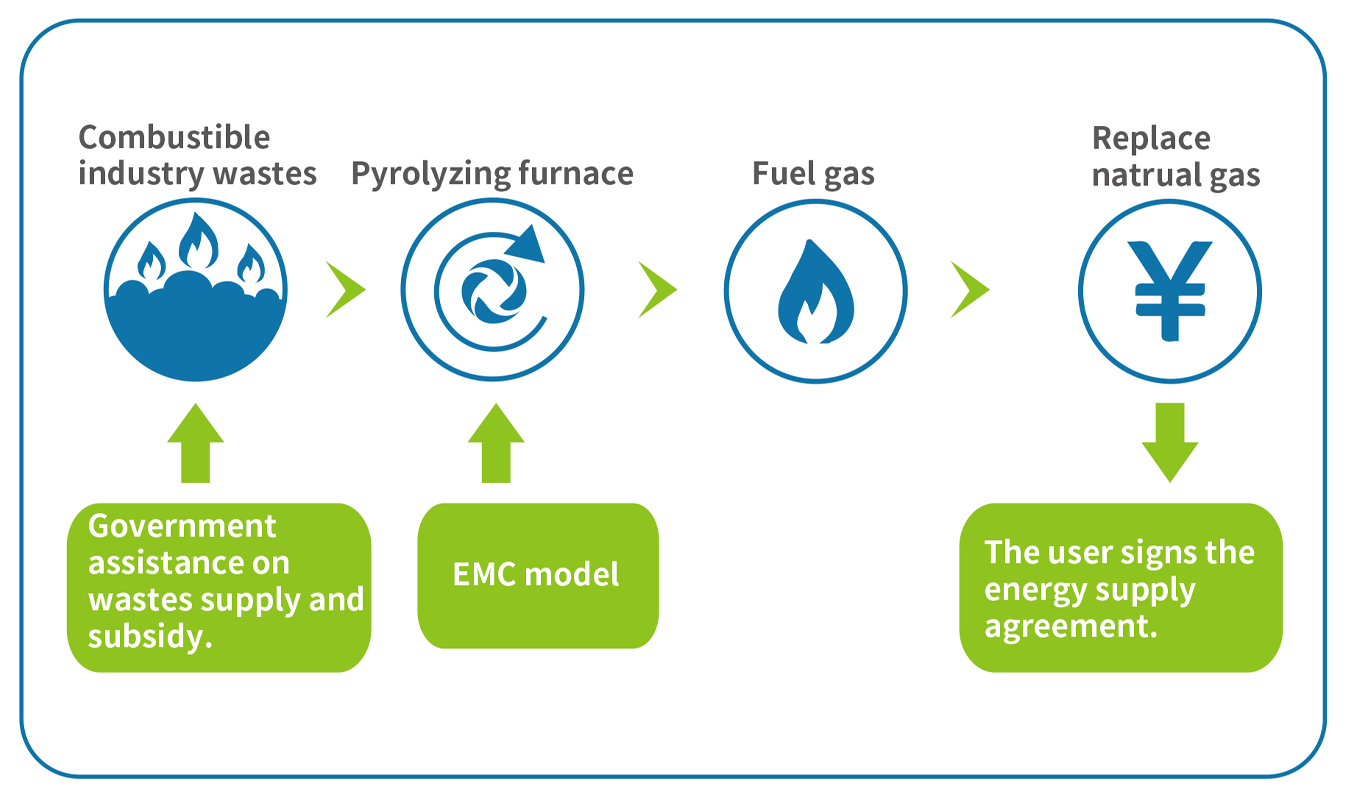

Schematic diagram of a typical industrial waste pyrolysis cycle model

Industrial waste pyrolysis treatment system advantages

● Realized the waste reduction and resource utilization.

● Low generation of dioxins and volatile organic compounds, low secondary pollution.

● Thermal energy reuse by syngas and char.

● Adjustable output products proportion according to the product demand.

● High integration, low land occupation, low investment and operating costs.

● Especially suitable for paper mill residue and other industrial combustible waste.

-

Next:Sludge